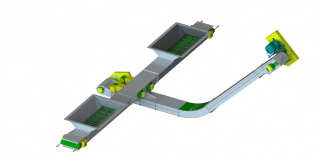

With a Sukup Chain Loop Conveyor, you can fill, unload, blend, and transfer grain in one complete operation. Loop Systems generally require less power and are gentler on grain than augers. The flexibility of Loop Systems make them great for adding to existing site or incorporating into a new site. A vertical loop works in a system where bin centers are aligned and the center sumps dump into the chain loop tube installed under the bin floor. A slanted loop is used in a system where the fronts of the bins are aligned and the external powerheads discharge into the chain loop tube.

Standard Features

- Use one piece of equipment for both filling and reclaiming

- Gentle and efficient handling of grain

- Access door on top of discharge spout for inspection and service

- Externally-mounted, heavy-duty pillow block bearings on drive corners

- Paddles are pre-attached to the chain, saving assembly time

- Corrosion-resistant Acme thread take-up screws at inspection corner

Product Accessories

- Optional gravity take-up

- Electric motor drive for discharge gate control

- Rubber clean-out paddles remove any residual grain not removed by UHMW paddles

- Power sweep can be integrated into system with optional paddle sweep

- Several inlet options, including drive-on truck dumps are available

- Band-on view ports for checking fill rate

Product Features

- Easily Expandable for Future

- Premium UHMW Paddles Eliminate Steel-to-Steel Contact

Justin Louk, Louk Ag Services LLC, Empire Ag LLC

Iowa

The thing I like the most about working with Sukup is their ability to listen and integrate what the customer would like to see. You know the guys out in the field they’re the ones that really know how this stuff should go together. They implement a lot of ideas that we have.